|

To avoid crushing and ruining parts, Swiss precision manufacturer Micro-Matics turned to Masa Tool’s Microconic collet and cartridge system. by Bernard Martin & Elizabeth Engler Modic, Today's Medical Developments May 2022 Since 1973, Micro-Matics of Fridley, MN, has been manufacturing CNC Swiss precision screw machine products including many kinds of contacts & pins, ground shafts, hardened bushings, rivets, screws, spacers and other custom parts for the medical, dental, aerospace, commercial, defense, computer, telecommunications and automotive industries. According to Jason Wobig, Operations Manager, "Micro-Matics is primarily an aerospace and medical components, Swiss machining job shop. We make components that are thousandths of an inch up to an 1-1/4" in diameter. We started out with the old manual style, Cam driven Swiss machines and we're one of the largest Escomatic shops in the Midwest. And as the company's grown and evolved, we've turned into Swiss job shop, mostly Citizen machines like the M16, a L12, and a M32, as well as a few Star and Tsugami machines that give us a wide variety of capabilities." Medical part challenges

High Tech Industrial Representation, Inc, or "High Tech" is a manufacturer's representative agency managing the territories of Minnesota, North Dakota and South Dakota, as well as Iowa & Nebraska. They represent industrial manufacturers whose products are focused on the machining industry and provide a high level of technical sales support. Todd brought in Masa's F20M10 Cartidge and the specific off-the-shelf Micorconic collet for the catheter part.

The Micrograd wrench allows you to set your collet clamping force so even the most fragile parts can be held safely and firmly according to Matt Saccomanno, CEO of Masa Tool. Cartridge and collet solutionIn 1996, Matt Saccomanno, CEO of Masa Tool, was frustrated with the limitations of conventional collets and workholding systems when performing secondary machining operations so his solution was to develop a high-precision, collet-type workholding device for small parts machining. The Microconic system consists of a cartridge and collet, with the cartridge fitting in the machine just like a standard legacy collet. The cartridge is a self-contained precision mechanism using the machine’s standard collet closing function, which means that the Microconic system can be used on any machine utilizing 5C, TF20, TF25 or TF37 collets. According to Saccomanno "Since a collet system for any given machine must be made large enough to fit the maximum workpiece diameter capacity of the machine, the result is the standard collet mechanism is designed to handle the largest workpieces, which means it is excessively forceful and bulky when used for the smaller workpieces. Smaller parts get sacrificed, because they typically require a higher degree of accuracy and the workholding is more critical." The Microconic system consists of the cartridge, which fits into your machine like a standard collet, and the Microconic collets which fit into Masa's unique cartridge. Every Microconic cartridge comes standard with extended nose for unsurpassed rigidity because of it's single piece construction. "In fact, the cartridge is so accurate that it can be used as a gauge to verify machine spindle accuracy," said Pakiz. Thayer explained how the Microconic system has worked for Micro-Matics "With the Masa system we're able to dial in a nice specific tension to hold that catheter part without crushing it or deforming it at all and having it on center. In a nutshell, we get better quality parts consistently with tighter tolerances. It's lead to a really significant improvement, it's increased throughput, so we have more parts at the end of the day." "As a result of the implementation, the scrap rate on this part dropped dramatically once we added the new Masa system by at least 30%." added Wobig. According to Masa Tool, the Microconic cartridge concentricity is guaranteed to be within 5µm (.0002") runnout and the collets are hardened and precision ground to the highest quality standards. The regular, UM10, 10mm collets, that Micro-Matics is using in their F20M10 Cartidge are available from Ø0.2mm (.008") to 10mm (.394"). In additon to the TF 20 spindles, the same collets can be used in TF25, TF37 and 5C sub spindles. Applying technology to other applicationsAs time has gone on Masa's Microconic system has propagated to other machines and other jobs. Micro-Matics has been running one of the collets for a couple of months straight now on a distal coupler. Thayer explains, "The distal coupler part has a unique shape. It's not perfectly round. It has some small flats milled on either side of the part. It's like a cylindrical pill, like a capsule except with two sides of the long length milled in so there's flats on it. The part is 0.080" in length 0.040" in a cylindrical diameter. We then mill the cylindrical diameter 180 degrees from each other to a thickness of 0.030", so you're taking 0.10" off then drilling and centering two holes on each end of that through the flats." "Our customer is extremely concerned about any collet indication marks or chip marks on the outside of that cylindrical diameter. The previous collets we were using were custom made collets that actually had the profile of the part basically machined into it" says Wobig.

So what happened when they started using the Microconic system? "It fixed all that!" said Thayer. Remedying the issues"With the Microconic system, we didn't need to buy any special collets for any specific profile, we just got the actual diameter for the OD of the part and we're running it with that. The spaces in between on that collet is small enough that it's not distorting the round to flat portion if it even gets into there at all. So there's no timing issues at set-up. We just put it in there, set our tension, and start picking them off." added Wobig Thayer continued "The extended nose pieces on the Microconic cartridge helps on the catheter tips because you can get closer up to where I actually have a supporting back end. Because if I'm too far away from that supporting back and you have more of a tendency to crush the front of that part. The Microconic gives me a better tension on the part. On the distal coupler, we have to use a boring bar, or a facing tool to create the back face, which is round. We'd have a lot of trouble trying to hold without nibs or anything on there. And this holds it so that the part stays a little more square, and we're able to turn it better." When dealing with very small parts and setting with small gage pins, accidents do sometimes happen. "The only problem I've had with it was when somebody was trying to set the collet tension with a pin. They put the pin into the slot and not the hole and wrecked the collet. Because the pin was able to fit inside the slot so when they started tightening it up, and the pins started deforming the collet was wrecked because it wasn't in the hole in the center." said Thayer. Masa has indicated that they will release a new TF 15 and TF16 Cartridge with an entire series of smaller 5mm capacity collets at IMTS 2022. SpecificationsOver-grip 10mm collets from 0.5mm to 7.2mm diameter (0.020" to 0.283") open to 4mm (0.157") diameter larger than the clamping diameter. Some restrictions apply to larger sizes approaching the 7.2mm (0.283") max diameter.

Microconic over-grip collets have unmatched rigidity and concentricity compared to other manufacturers. The same collets can be used in TF20, TF25, and 5C sub spindles. Microconic collets permit interchangeability between machines, and the collets fit in any Microconic cartridge, no matter which collet system is in the machine.

0 Comments

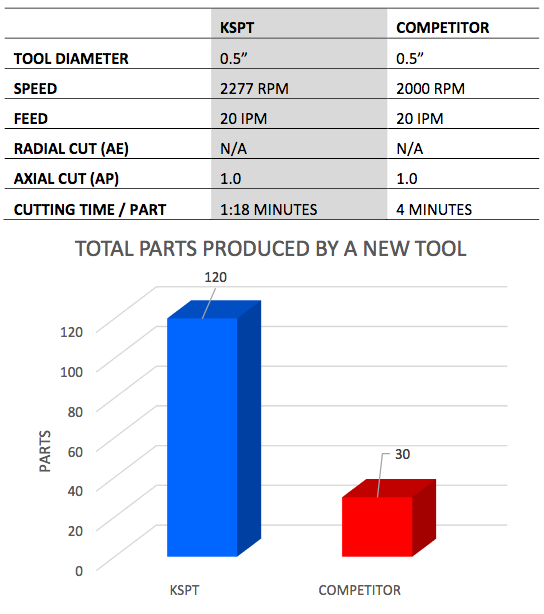

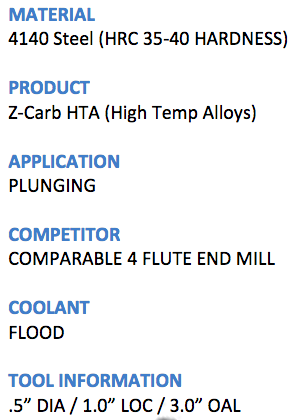

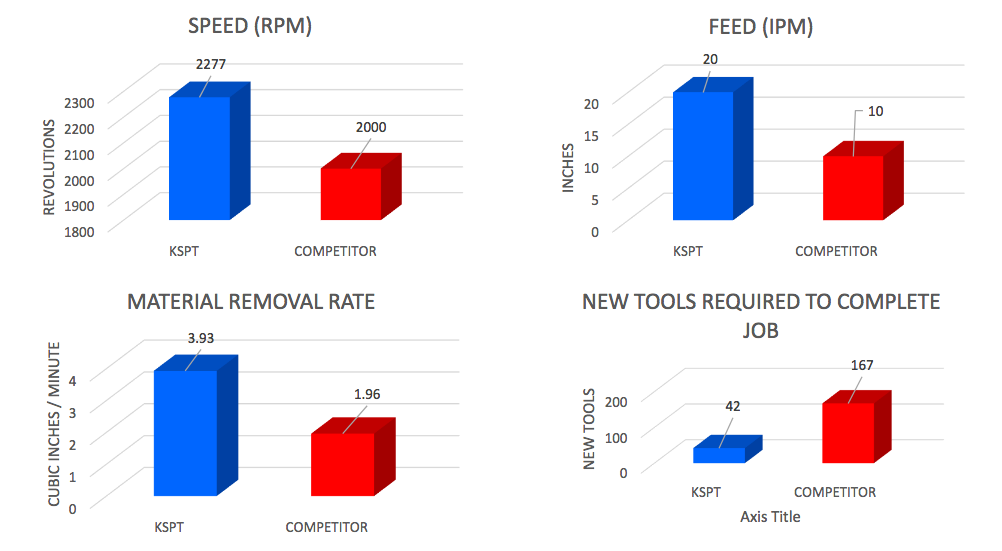

GOALS The goals of this study were to significantly reduce job cost through increasing tool life and maximizing operating efficiencies

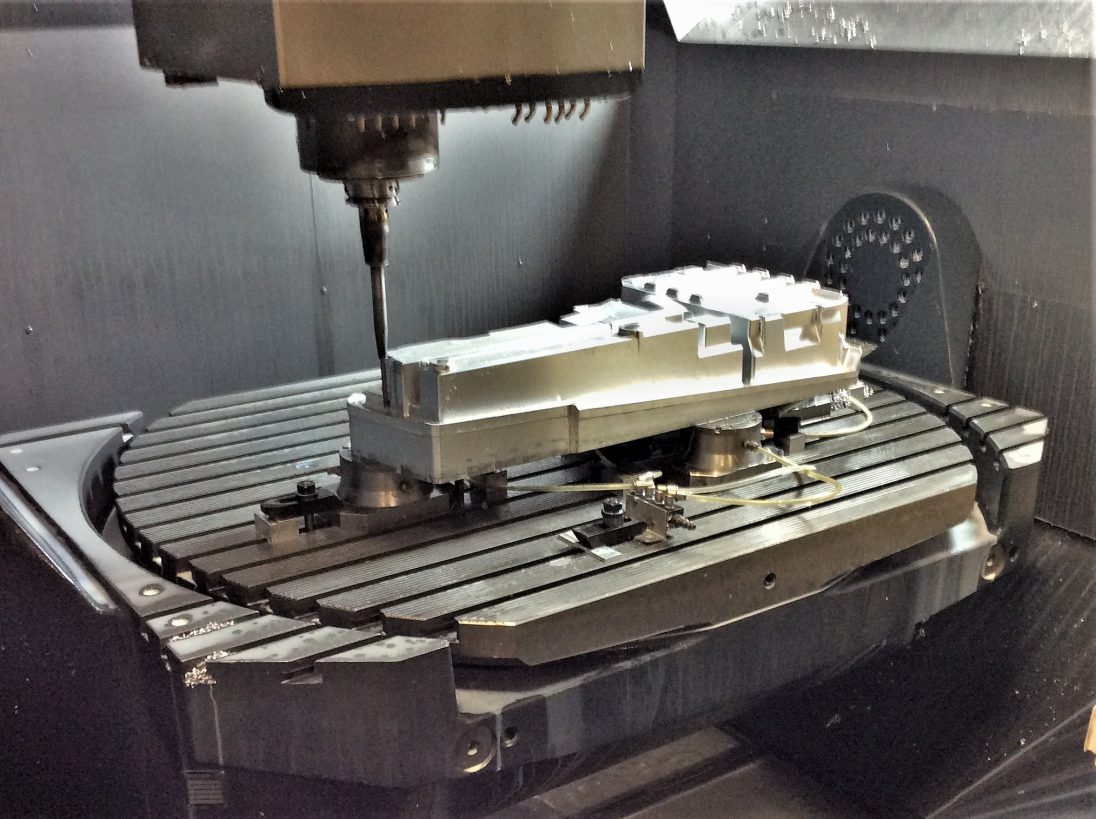

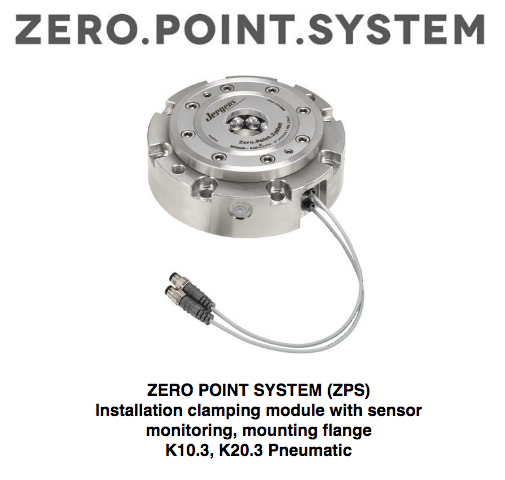

Case Study: Toronto Mold & Die Shop Cuts Set-up Time by 90% with Modular, Quick Change Workholding5/16/2018 With forty years under their belt, 120 employees, multiple customers with different machining and material demands, and a successful business, the shop turned to Jergens in 2015 to explore options for a better way. A better way to hold the large variety of components that the shop had grown to manufacture for its customers in the mold and die industry. They did, and they did it so well it earned them a reputation in the industry as ‘the aluminum experts’. The Workholding Challenge The shop had to build and maintain over 150 different custom fixtures of widely varying configurations. Furthermore, products produced spanned eight different categories, required expertise in CAD, engineering, prototype parts, machining operations including five axis, tooling and the list goes on. In addition to ordering a range of steel sub plates, fixture plates and numerous clamping components to make the fixtures, the shop also had to machine and assemble them. So, before a single chip hit the floor from a customer part, they had to make their own set ups. They did well, obviously they are a skilled shop, but realized that a better solution had to exist. Jergens Workholding Solution

The Results For the shop, the biggest realization (economic impact) came from the analysis of the true cost to manufacture and assemble the fixtures, and the incredible reigning-in of set up time – 90% reduction.

Prior to the Jergens ZPS solution, the time it took for each set up was ten minutes, and there was an average of thirty setups – that’s five hours per day spent just in setup time. That average time with the change to ZPS went to just one minute, or one-half hour total per day. At a rate of $100 per hour, that’s $450 per day in savings, or $112,500 annually! Tom Reid, Canadian Sales manager for Jergens, who works very closely with the shop, reported, “I’ve seen a lot of positive results, particularly with Drop and Lock (another popular quick-change pallet option) and ZPS, but don’t recall one as dramatic as this in recent years”. Tom continued, “We work closely with the customer to engineer and provide these solutions, and also measure important calculations such as ROI, which in this case was about five weeks”. The end result for part production was significant and predictable - error reduction, reduced scrap, easy part orientation, and better / more consistent output from the manufacturing floor. |

News & Applications

Learn about the latest breaking news and applications that we're working on right here! Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed