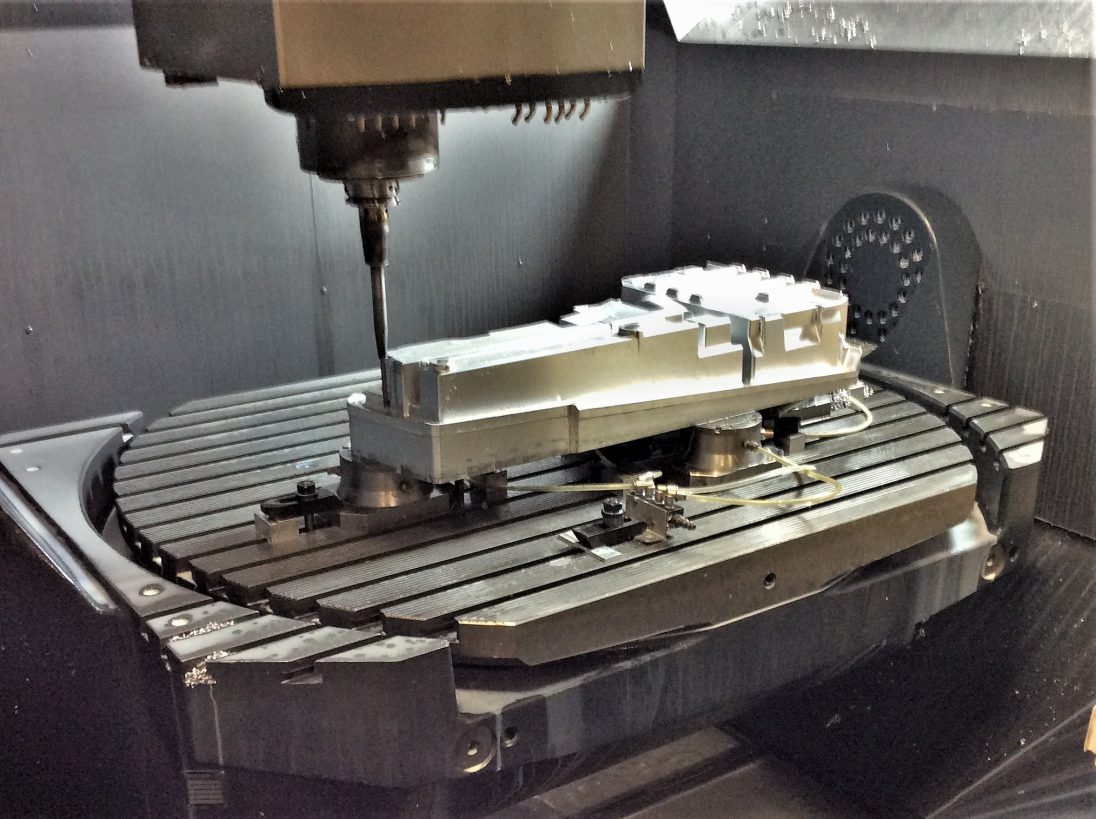

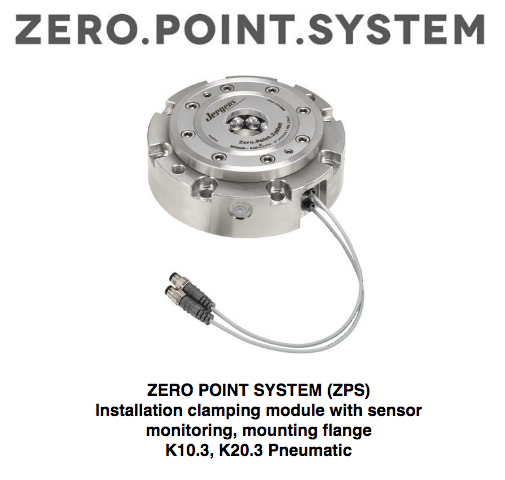

Case Study: Toronto Mold & Die Shop Cuts Set-up Time by 90% with Modular, Quick Change Workholding5/16/2018 With forty years under their belt, 120 employees, multiple customers with different machining and material demands, and a successful business, the shop turned to Jergens in 2015 to explore options for a better way. A better way to hold the large variety of components that the shop had grown to manufacture for its customers in the mold and die industry. They did, and they did it so well it earned them a reputation in the industry as ‘the aluminum experts’. The Workholding Challenge The shop had to build and maintain over 150 different custom fixtures of widely varying configurations. Furthermore, products produced spanned eight different categories, required expertise in CAD, engineering, prototype parts, machining operations including five axis, tooling and the list goes on. In addition to ordering a range of steel sub plates, fixture plates and numerous clamping components to make the fixtures, the shop also had to machine and assemble them. So, before a single chip hit the floor from a customer part, they had to make their own set ups. They did well, obviously they are a skilled shop, but realized that a better solution had to exist. Jergens Workholding Solution

The Results For the shop, the biggest realization (economic impact) came from the analysis of the true cost to manufacture and assemble the fixtures, and the incredible reigning-in of set up time – 90% reduction.

Prior to the Jergens ZPS solution, the time it took for each set up was ten minutes, and there was an average of thirty setups – that’s five hours per day spent just in setup time. That average time with the change to ZPS went to just one minute, or one-half hour total per day. At a rate of $100 per hour, that’s $450 per day in savings, or $112,500 annually! Tom Reid, Canadian Sales manager for Jergens, who works very closely with the shop, reported, “I’ve seen a lot of positive results, particularly with Drop and Lock (another popular quick-change pallet option) and ZPS, but don’t recall one as dramatic as this in recent years”. Tom continued, “We work closely with the customer to engineer and provide these solutions, and also measure important calculations such as ROI, which in this case was about five weeks”. The end result for part production was significant and predictable - error reduction, reduced scrap, easy part orientation, and better / more consistent output from the manufacturing floor.

0 Comments

|

News & Applications

Learn about the latest breaking news and applications that we're working on right here! Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed