|

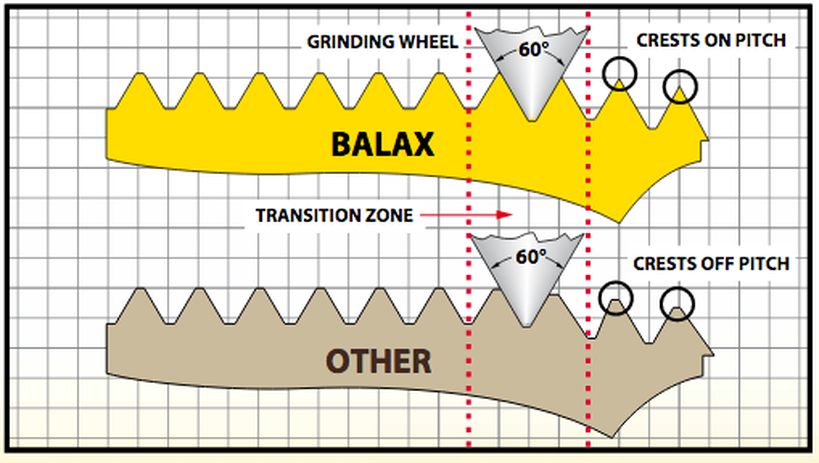

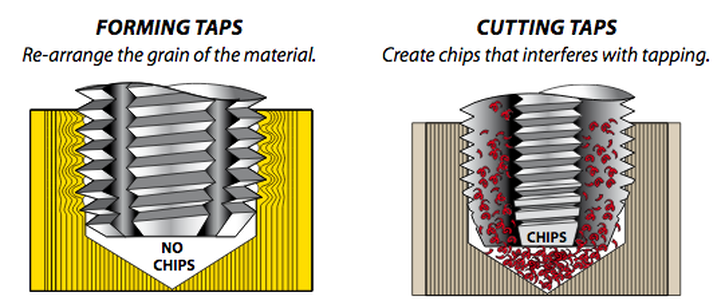

Forming taps displace metal — cutting taps remove it. BALAX stands for “BALanced AXially,” which is an important feature for all of our Thredfloer Cold Forming Taps. Balax Thredfloers are ground using our proprietary thread grinders that have a differential lead compensation device that produces cold forming taps with their lead crests exactly on pitch. Other forming taps have lead thread cold forming teeth that are not ground on pitch. These forming taps actually cold-work the thread twice:

Balax Thredfloers form the thread exactly on pitch the first time with no axial thrust, hence the name “BALanced AXially”. All Thredfloers require less tapping torque and provide longer tap life than forming taps ground with conventional methods. Forming taps and cutting taps produce threads that gage identically and are interchangeable, but the similarity stops there. The way they produce threads is completely different:

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

News & Applications

Learn about the latest breaking news and applications that we're working on right here! Archives

June 2022

Categories

All

|

RSS Feed

RSS Feed